Morphing Shield Technology

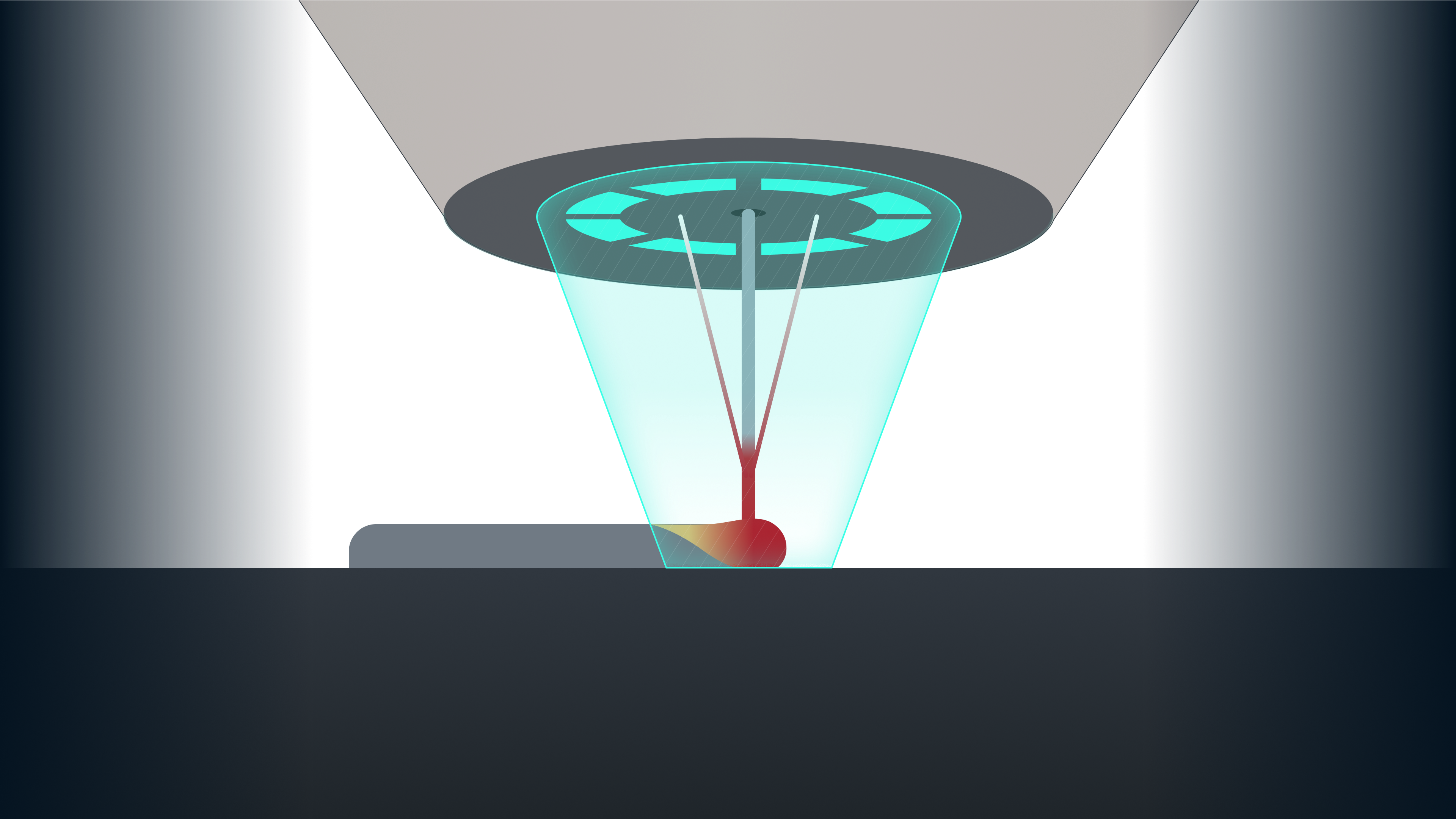

Morphing Shield Technology builds a portable inert gas environment surrounding the melting zone for laser wire DED processes.

Can we overcome the constraints in traditional 3d printing with portability?

Morphing Shield Algorithm

Optimizing the printing process with section-based gas pressure adjustment.

Morphing Shield Algorithm adjusts the inert gas supply according to the geometry to maintain low oxygen levels.

Morphing Shield Section

Inert Environment

Real-time Oxygen Control

Oxygen sensor operates during printing to ensure a stable inert environment sustains.

oxygen level sensing

Ti-64 Print Samples

Our print samples come at varying and unlimited scale, with oxygen content of 0.15%, passing Ti-64 Grade 5 standards.

Technological Competitiveness

How we shift industry standards

Break Spatial Limitations

Morphing Shield is the industry's first technology to enable a portable inert environment, allowing printing of metal parts without size limitations in additive manufacturing.

Precision Meets Speed

LabAM24’s technology challenges conventional layer height limits, achieving thicknesses under 1mm, while maintaining travel speed.

Real-Time Troubleshooting

Using Morphing Shield, operators can implement immediate corrective actions without the need to reconfigure the inert chamber.

Streamlined for Maximum Savings

The development of the portable inert environment eliminates all chamber setup costs, significantly reducing expenses.